TPV-TPE GASKET

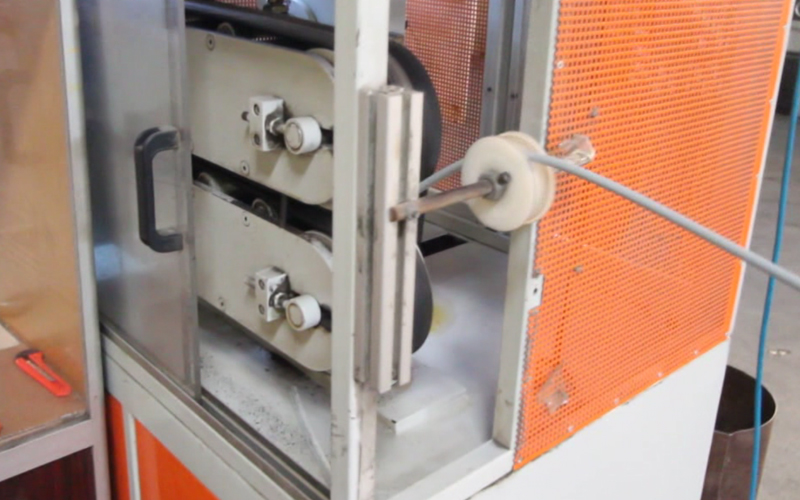

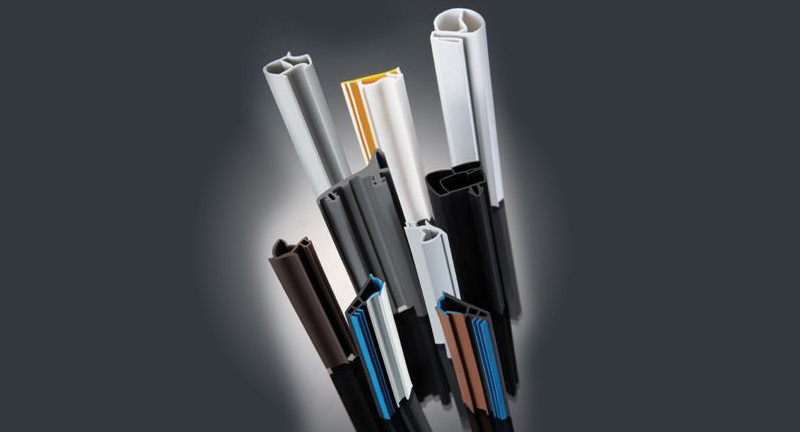

Thermoplastic Vulcanizate (TPV-TPE) is a positive product with colouring and welding capabilities that has a wide area of application in construction, PVC profiles, aluminium applications, the automotive industry and the domestic appliances industry. A variety of solutions can be developed according to technical design and intended purpose, and the design varies in line with intended use. Our TPV-TPE Gasket plant serves our customers with an annual production capacity of 36.000.000 meters through the use of 3 extruders.

Flexibility in Design

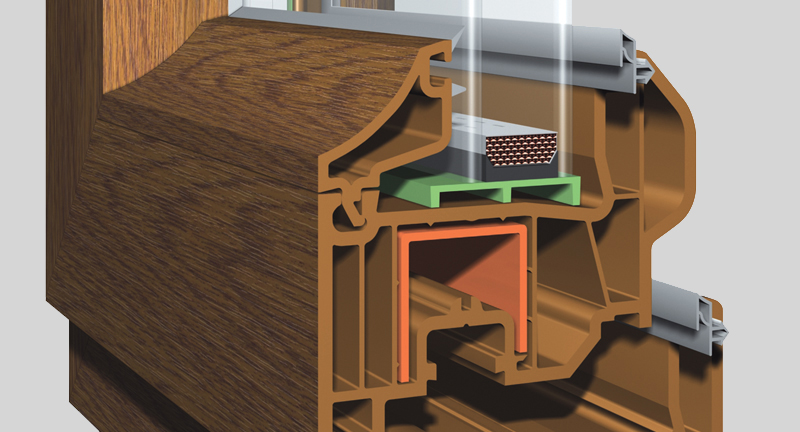

The TPV-TPE's are easily coloured. The profiles and parts can be easily welded and assembled with heat. It allows the design of slim profiles without compromising imperviousness.

Superior Imperviousness

Demonstrates excellent resistance without cracking and breakage. Ensures long-term perfect imperviousness. May be used without breakage and loss in its impervious character in much colder weather conditions compared to EPDM.

Weather Resistance

Resistant against ultraviolet light. Allows use on a wide temperature range. Preserves its flexibility in cold weather too. Highly resistant against ozone and chemicals.

Compatibility with Other Materials

Compatible with polycarbonate and acrylic type materials. Does not cause such materials to crack or fracture. Does not keep on water-based paint used on wooden window systems, and is easily cleaned.

Fields of Use

In the Automotive, Architecture, Construction, Electricity, Electronics, Medical and Foodstuffs industries, and as impact resistance booster in elastomeric goods, office equipment, PP and PE plastics.

Quality

Adopting the highest level of quality and customer satisfaction as its principle, our company operates rigorously in all processes in order to take its place among the leading corporations of its sector in the TPV-TPE Gasket sector and its sale.